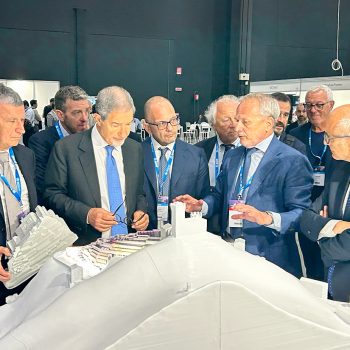

From June 30th to July 5th 2024, Milan hosted the Earthquake Engineering Conference (WCEE2024), a highly relevant event for experts in the field and institutions we have written extensively on these pages. During the opening day on July 1st, at our Foundation’s stand, Minister Musumeci, together with Senator and Extraordinary Commissioner for Post Earthquake Reconstruction 2016 Guido Castelli and the Head of the Civil Protection Department Fabrizio Curcio, were able to take a close look at the model of the Arquata del Tronto reconstruction project.

An Innovative Project for Reconstruction

The project to rebuild the historic centre of Arquata del Tronto, devastated by the 2016 earthquake, received the official green light on 29 June. This ambitious plan includes structural consolidation to ensure the area’s safety and resilience. But what caught the most attention during the conference was the scale model of the project, created by the ProtoLab laboratory of the Department of Civil Engineering and Architecture of the University of Pavia (DICAr).

The Communicative Power of a 3D Model

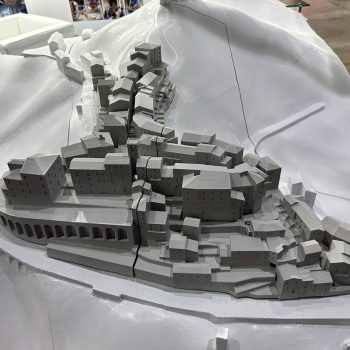

The model of the “Soil Project in the Historic Centre of Arquata del Tronto” was designed to make the structural consolidation works immediately understandable to a wide audience with different skills. Using a 3D physical model instead of the traditional 2D visualisations of drawings and project boards allowed the consolidation works to be represented more effectively.

The ground beneath the block of flats destroyed by the 2016 earthquake was made of a transparent photopolymer, allowing visualising steel tie rods, convergence shafts, and reinforcement walls. An adjustable lighting system further enhanced the visual contrast and representation of details, making the model extremely faithful to the executive design.

The Complexity of Realisation

The model’s creation required the use of two different 3D printing technologies and various CAD/CAM software. The transparent terrain part was created using the Stratasys J750 Digital Anatomy additive manufacturing system, while the hill and the block were made from polylactic acid (PLA) using Free Form Fabrication additive manufacturing systems.

The production process involved creating nine basic blocks for the hill and fourteen total components, which were glued, grouted, and painted. The block was made in three parts, and the transparent ground in five blocks. The 3D printing took 28 days, while the processing of the design files and the final assembly with painting and lighting took approximately one man-month and seven days, respectively.

The Protagonists of the Project

The model was commissioned by the Marche Region – Special Office Department for Marche Reconstruction and realised by ProtoLab based on the project provided by Fondazione Eucentre. DICAr took care of administrative management.