Dipartimento Prodotti Industriali

Prove per la qualifica di dispositivi di appoggio strutturale e dispositivi antisimici

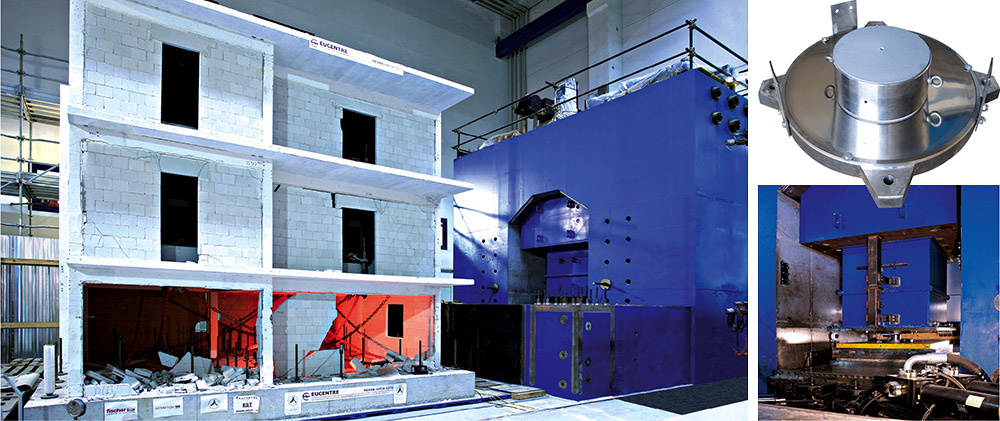

La Fondazione EUCENTRE si occupa dal 2007 di prove su dispositivi di appoggio strutturale e dispositivi antisismici (isolatori e dissipatori).

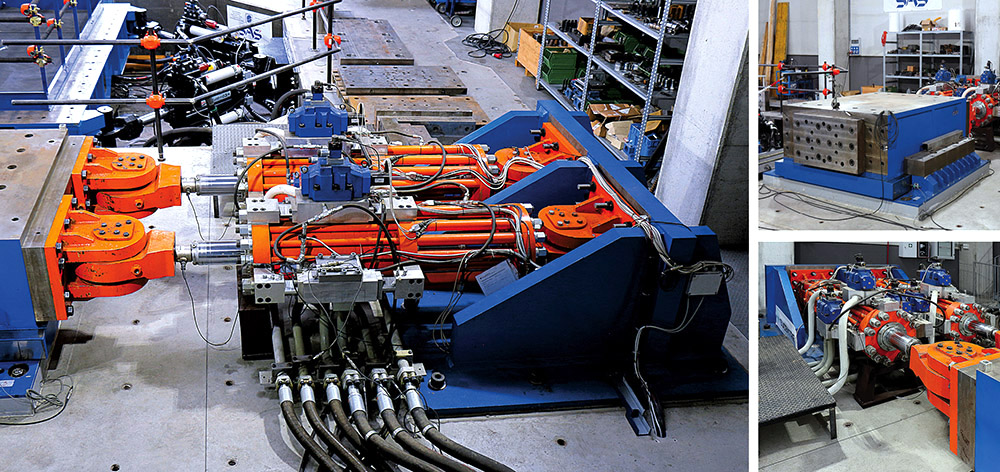

I laboratori EUCENTRE hanno a disposizione due apparati di prova:

- “BTS” (Bearing Testing System) dedicato alla caratterizzazione sperimentale di dispositivi di appoggio strutturale (appoggi in gomma armata, appoggi POT e appoggi sferici) e isolamento sismico (isolatori a strisciamento e in gomma);

- “DTS” (Damper Testing System) dedicato alla caratterizzazione di dispositivi di smorzamento (dipendenti dallo spostamento e dalla velocità) e di vincolo dinamico.

La Fondazione EUCENTRE vanta un’esperienza pluriennale guadagnata con l’esecuzione di prove su oltre 3’000 isolatori, 1’500 appoggi strutturali e 200 dissipatori.

Si eseguono protocolli di prova secondo i principali standard internazionali (EN1337 – Structural Bearings, EN15129 – Antiseismic Devices e AASHTO) o si sviluppano, in accordo con il cliente, campagne sperimentali di ricerca e sviluppo personalizzate.

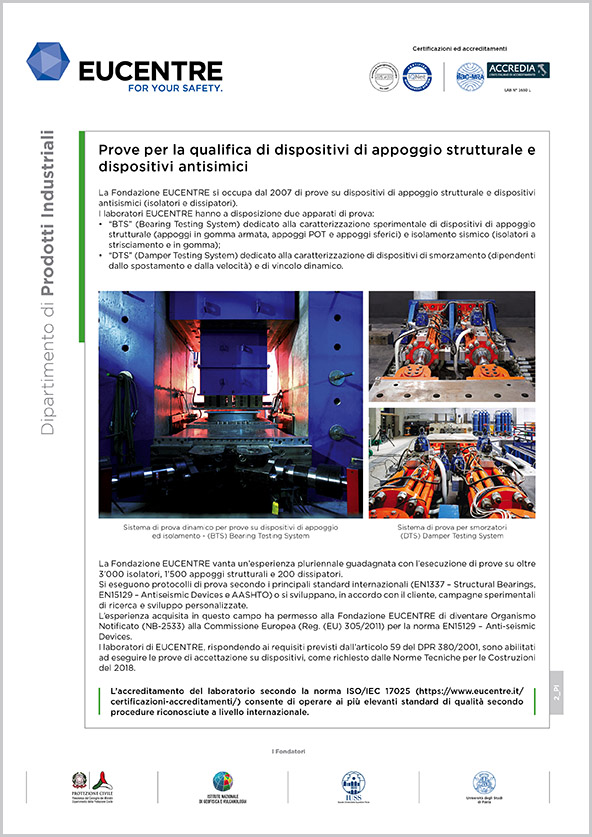

Sistema di prova dinamico per prove su dispositivi di appoggio ed isolamento

(BTS) Bearing Testing System

Dimensioni della tavola: 1.6 m x 4.4 m

Spostamento massimo: Long. ± 495 mm, Trasv. ± 265 mm, Vert. ± 75 mm

Velocità massima: Long. 2200 mm/s, Trasv. 600 mm/s, Vert. 250 mm/s

Accelerazione massima: ± 1.8 g

Massima portata olio: 11000 + 16000 l/min

Forza statica massima: Long. 1900 kN, Trasv. 1000 kN, Vert. 40000 ± 10000 kN

Forza dinamica massima: Long. 1700 kN, Trasv. 750 kN, Vert. 40000 ± 10000 kN

Massa mobile: ~ 22.1 t

Momento ribaltante massimo: 20000 kNm

Range operativo di frequenze: 0-20 Hz

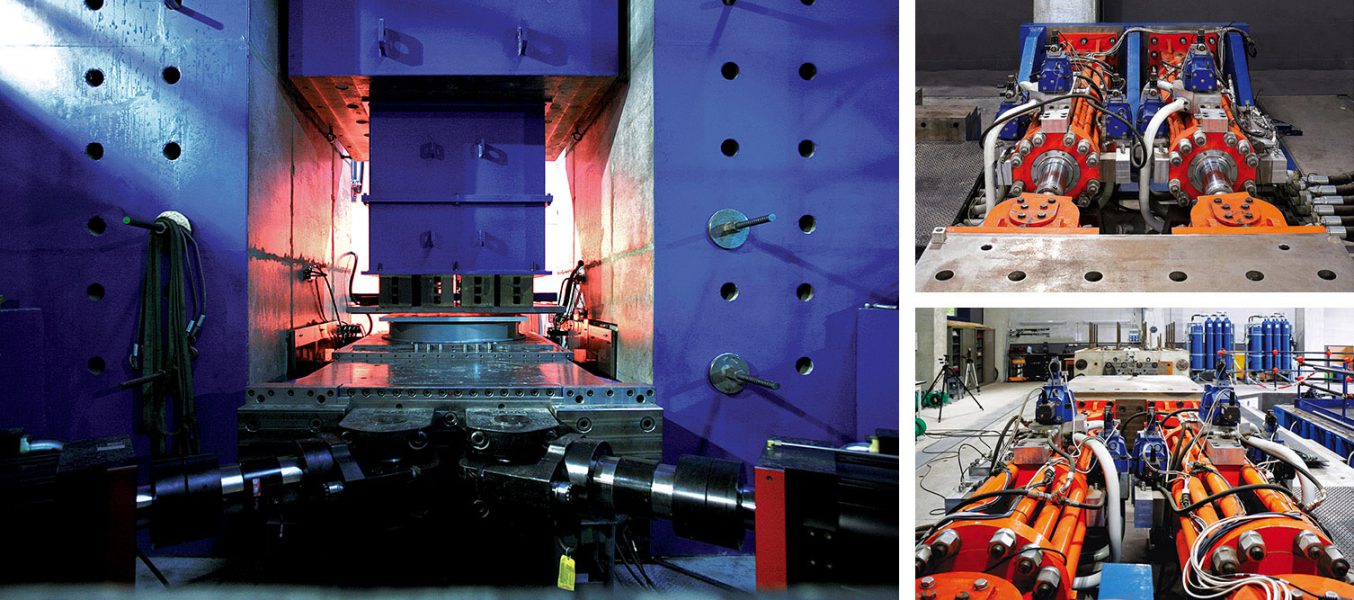

Sistema di prova per smorzatori

(DTS) Damper Testing System

Lunghezza massima provini: 8000 mm

Diametro massimo provini: 1200 mm

Spostamento massimo: ± 250 mm

Velocità massima: 1100 mm/s

Massima portata olio: 3000 l/min

Forza massima: 4400 kN

L’accreditamento del laboratorio secondo la norma ISO/IEC 17025 consente di operare ai più elevanti standard di qualità secondo procedure riconosciute a livello internazionale.

[easy-social-share buttons=”facebook,twitter,google,pinterest,linkedin,whatsapp” counters=0 style=”icon” point_type=”simple”]

Eucentre è una Fondazione di diritto privato senza scopo di lucro che persegue una missione di ricerca, formazione e erogazione di servizi nel settore dell’ingegneria sismica e, più in generale, dell’ingegneria della sicurezza

Eucentre è una Fondazione di diritto privato senza scopo di lucro che persegue una missione di ricerca, formazione e erogazione di servizi nel settore dell’ingegneria sismica e, più in generale, dell’ingegneria della sicurezza  Eucentre promuove Scienza, Ricerca e Innovazione a beneficio della collettività, offrendo metodologie mirate e soluzioni concrete per prevenzione, sicurezza e resilienza. Collabora con istituzioni e imprese, diffondendo competenze orientate al vantaggio comune.

Eucentre promuove Scienza, Ricerca e Innovazione a beneficio della collettività, offrendo metodologie mirate e soluzioni concrete per prevenzione, sicurezza e resilienza. Collabora con istituzioni e imprese, diffondendo competenze orientate al vantaggio comune. Eucentre conduce ricerche sull’ingegneria sismica e sulla riduzione del rischio attraverso test di laboratorio e analisi numeriche. L’obiettivo è migliorare il comportamento sismico delle strutture e dei terreni e sviluppare tecniche innovative antisismiche

Eucentre conduce ricerche sull’ingegneria sismica e sulla riduzione del rischio attraverso test di laboratorio e analisi numeriche. L’obiettivo è migliorare il comportamento sismico delle strutture e dei terreni e sviluppare tecniche innovative antisismiche  Eucentre conduce attività di ricerca su ingegneria sismica e riduzione del rischio, attraverso prove di laboratorio e analisi numeriche, per migliorare il comportamento sismico di strutture e terreni e sviluppare tecniche innovative di consolidamento antisismico.

Eucentre conduce attività di ricerca su ingegneria sismica e riduzione del rischio, attraverso prove di laboratorio e analisi numeriche, per migliorare il comportamento sismico di strutture e terreni e sviluppare tecniche innovative di consolidamento antisismico. La Fondazione promuove attività formative diversificate e di alta qualità, rivolte a contesti accademici e professionali, con programmi e iniziative costantemente aggiornati e innovativi per rispondere alle esigenze in continua evoluzione del settore e della società

La Fondazione promuove attività formative diversificate e di alta qualità, rivolte a contesti accademici e professionali, con programmi e iniziative costantemente aggiornati e innovativi per rispondere alle esigenze in continua evoluzione del settore e della società  Eucentre assicura una comunicazione per informare istituzioni, professionisti e cittadini sulle attività e i progetti in corso, con l’obiettivo di diffondere contenuti e conoscenze utili e accessibili a tutti. Contribuisce a promuovere una cultura della prevenzione e della resilienza, condivisa e consapevole.

Eucentre assicura una comunicazione per informare istituzioni, professionisti e cittadini sulle attività e i progetti in corso, con l’obiettivo di diffondere contenuti e conoscenze utili e accessibili a tutti. Contribuisce a promuovere una cultura della prevenzione e della resilienza, condivisa e consapevole.